The alternation of sun and moon, the flow of light and shadow

The coordinate axis of time and space

Engrave the footprints of every step of struggle

The shutter sound of memory

Freeze the moment of each frame’s struggle

Only by settling down the past can we plan for the long term

Ready to set sail, ready to set sail

The sun and moon move forward, and the golden age is new

Let’s look back on 2023 together

Inventory our annual keywords

Mountains and rivers are vast, and we move forward with great strength

The scroll of history unfolds in the process of forging ahead; The chapter of the times is written through unremitting struggle! We have ushered in the Chinese New Year holiday amidst wind and rain. On this occasion of praying for blessings and welcoming the new year, Hanas LNG Plant extends sincere gratitude to friends from all walks of society who have cared for and supported the development of the enterprise over the past year, and extends sincere New Year greetings to all staffs and their families who have worked hard for the development of the enterprise! Standing at the annual threshold for inventory, looking back on the arduous journey, we have always adhered to the tradition of striving day and night, with unwavering beliefs and overcoming obstacles. We have not only witnessed struggle and breakthroughs, but also witnessed growth and gains.

Safety First and Casting Excellent

4223 days for safe operation

0 accidents

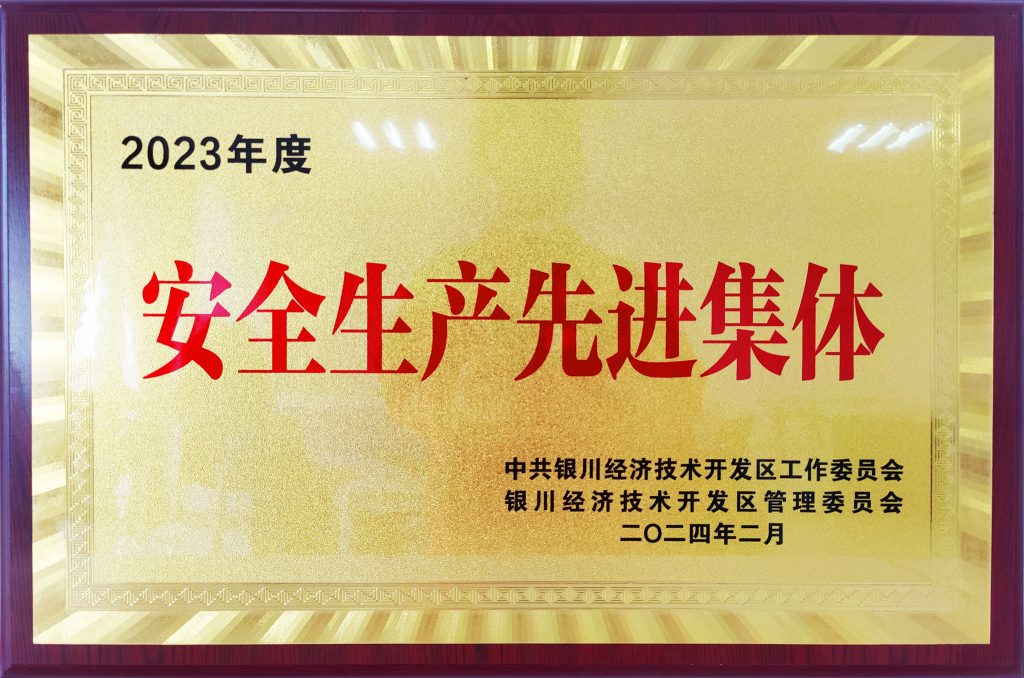

Hanas LNG Plant was officially put into operation on July 18, 2012, and has been operating safely and steadily for 4223 consecutive days without any safety accidents. The company always regards safety production as its primary goal and task, firmly establishes the concept of safety development, and adheres to the bottom line of safety production red line; Strengthen the main responsibility of enterprises and implement the system of full staff safety production responsibility; Establish sound safety regulations and strengthen the construction of standardized management systems; Continuously improve the dual prevention mechanism and promptly eliminate accident hazards; Solidly carry out safety education and training to enhance the safety skills and quality of all Staffs; Continuously promote practical emergency drills and improve emergency response capabilities. We have carried out multiple special actions, including in-depth investigation and rectification of major accident hazards, and comprehensive investigation and rectification of safety production. Throughout the year, we have received 51 inspections from government regulatory departments at all levels of the country, autonomous region, Yinchuan city, and Economic Development Zone. Through exchange and learning, learning from each other’s strengths and weaknesses, we have effectively improved our safety management level. The company has been awarded the honorary title of “Advanced Collective in Safety Production” by Yinchuan Economic and Technological Development Zone for three consecutive years.

Reduce cost, increase efficiency and keep improving

365 days for annual operation

179 maximum daily truck loading

In 2023, the production facilities of Hanas LNG Plant operate for 365 days throughout the year, with a maximum daily LNG filling capacity of 179 vehicles. By organizing regular production operation analysis meetings, comparing production operation data, strictly controlling gas consumption, electricity consumption, and auxiliary material consumption indicators, operating two production units under different working conditions and loads, and strictly controlling production costs, the consumption of raw material gas per ton of LNG production decreased by 12 standard cubic meters compared to 2022, and the consumption of production auxiliary materials decreased by 19%. In order to effectively address the impact of changes in upstream gas source components on the stable operation of the amine system, a special meeting was held to study and discuss, visit and research surrounding liquefaction factories, and conduct technical exchanges with multiple amine liquid manufacturers. The optimization selection and replacement of amine liquid were successfully completed. Strictly control product quality, conduct 16355 laboratory analysis samples, and report 127400 sets of data. The construction of a digital platform for dual prevention mechanisms and a smart management platform for mobile pressure vessels has been completed. Through intelligent terminals, on-site inspections, hazard investigation, and daily safety management have been carried out, improving the level of information management for hazard investigation and treatment.

Scientific Overhaul and Professional Maintenance

2836 preventive maintenance items

1580 corrective maintenance and repair items

In 2023, Hanas LNG Plant strengthened equipment life cycle management, implemented equipment maintenance plans and preventive maintenance work, ensuring the safe and efficient operation of equipment. A total of 4416 maintenance tasks were completed throughout the year, including 2836 preventive maintenance tasks and 1580 corrective maintenance tasks. The annual equipment maintenance work was successfully completed, providing strong equipment support for the company to successfully complete its annual production tasks. Under the premise of ensuring the safe and stable operation of the second production line, complete the maintenance tasks of the refrigerant compressor, motor, and gearbox of the core unit of the first production line. Through maintenance, potential equipment malfunctions and hazards were eliminated, effectively improving the performance of the core unit and ensuring long-term stable and reliable operation. Establish and improve a dual prevention mechanism for special equipment, strengthen standardized and standardized management of special equipment, achieve a 100% inspection rate for special equipment, a 100% inspection rate for special equipment safety accessories, and a 100% completion rate for mandatory inspection of safety equipment.

Skilled in planning and beneficial for innovation

In 2023, Hanas LNG plant solved technical problems and improved equipment operating efficiency through technological breakthroughs and innovation. Throughout the year, a total of 36 technical solutions and reports were completed, 9 technical changes were made, and a total of 20 rectification projects, facility maintenance and renovation were completed, including conducting LOPA analysis and SIL grading, ensuring the safety and integrity of the SIS system; The upgrade and renovation of the density level gauge for LNG storage tanks have been completed, enhancing the low-temperature detection capability of the equipment. By formulating reasonable inventory strategies, optimizing inventory structure, and conducting strict inventory checks, the rationality and effectiveness of spare parts safety inventory can be improved. To ensure the smooth progress of equipment maintenance work, a 12 version shut down maintenance plan was developed through the CMMS system with 4416 annual planned work orders. Strengthen the quality control of in site maintenance progress, timely correct deviations through the execution process, and ensure timely maintenance and repair of equipment and facilities. Developed a 10-year inspection and maintenance plan and schedule for core equipment such as compressors, dynamically and continuously follow up and improve to ensure the reliability of the equipment throughout its life-cycle.

Overall coordination and full support

In 2023, Hanas LNG plant takes overall coordination and service assurance as the foundation, continuously improves and enhances comprehensive management work, and improves standardized, institutionalized, and procedural management systems, providing solid support and guarantee for safe production work. By strengthening talent recruitment, optimizing employee structure, and building an excellent management team, there are 5 formal staffs with master degrees and 78 with bachelor degrees, accounting for 80%, including 4 senior engineers and 24 intermediate engineers; 1 first-class registered fire engineer and 12 intermediate registered safety engineers. Continuously strengthen skill training, inspire employees to learn internally through mentor-ship, and promote common growth among staffs. Actively striving and striving for excellence, we have won the first prize in the national team leader management skills competition for four consecutive years. Strengthen the construction of corporate culture, continuously build a safety brand that adheres to the bottom line of safe production, creates intrinsic safety, and strives to become an industry benchmark, to assist energy transformation in China and ignite a green and high-quality life!

Practicing responsibility with devotion and love

In order to promote the traditional virtues of “devotion, friendship, mutual assistance, and progress” of the Chinese nation, in 2023, under the guidance of the party branch from our plant, actively participate in public welfare undertakings, strengthen paired construction, and convey social warmth and care through practical actions. Through carefully planning the theme party day activities of the branch every month, we organized party members and key staffs continue to carry out assistance for vulnerable groups in the jurisdiction, and successively carried out love volunteer activities in six care centers, including Xixia Xingping Yangguangjiayuan Disabled Children Care Service Center, Ningxia Disabled Athletes Training School, and Xixia Xintiandi Elderly Care Center; We have formed a partnership with Tonganyuan community in Xixia district to carry out the “Volunteer Elderly Care and Passing on True Love” assistance and co construction activity. Over the past year, we have delivered more than 20 tons of supplies such as grain and oil, daily necessities, and learning supplies. By carrying out a series of public welfare activities, the disadvantaged groups in the jurisdiction have felt the care and warmth from the enterprise, built a bridge of love between the enterprise and the people in the jurisdiction, practiced corporate social responsibility, and created a harmonious and warm social atmosphere.

Keep up with the progress and strive to achieve great success

The journey of the great road is vast and boundless; The great road is like a stone, and the traveler has no boundaries. In the new year, we must effectively enhance our sense of mission, urgency, and responsibility to achieve our goals and tasks, unify our thinking, gather consensus, closely focus on the group’s strategic deployment, adhere to the concept of sustainable development, adhere to safe and stable gas supply, and effectively safeguard people’s livelihoods. In the new year, we will use refined management as a means, reduce costs and increase efficiency as measures, and create a standardized first level enterprise for safe production as the goal, continuously improving the level and ability of scientific management. In the new year, we must continue to maintain the high fighting spirit of perseverance, forge ahead with determination, write a new chapter, and open up a new future!