In order to conscientiously implement the decisions and arrangements of the CPC Central Committee and the State Council, and in accordance with the relevant work requirements of the 2023 Action Plan for Special Investigation and Rectification of Major Accident Hidden Dangers in the Autonomous Region, Yinchuan City and the Economic and Technological Development Zone, and constantly improve the company’s emergency response speed and emergency response capability, on the morning of July 5, Hanas LNG Plant and the Fire Rescue Brigade of Yinchuan Economic and Technological Development Zone carried out a comprehensive emergency rescue drill for major hazard installations at the first level, General Manager Ma Qixuan serves as the overall commander of the drill. This drill simulates the leakage and fire of the LNG storage tank loading pump outlet pipeline, resulting in personal injury. The company conducts a series of emergency response work, including emergency response, personnel evacuation, casualty treatment, fire extinguishing, and leakage point elimination.

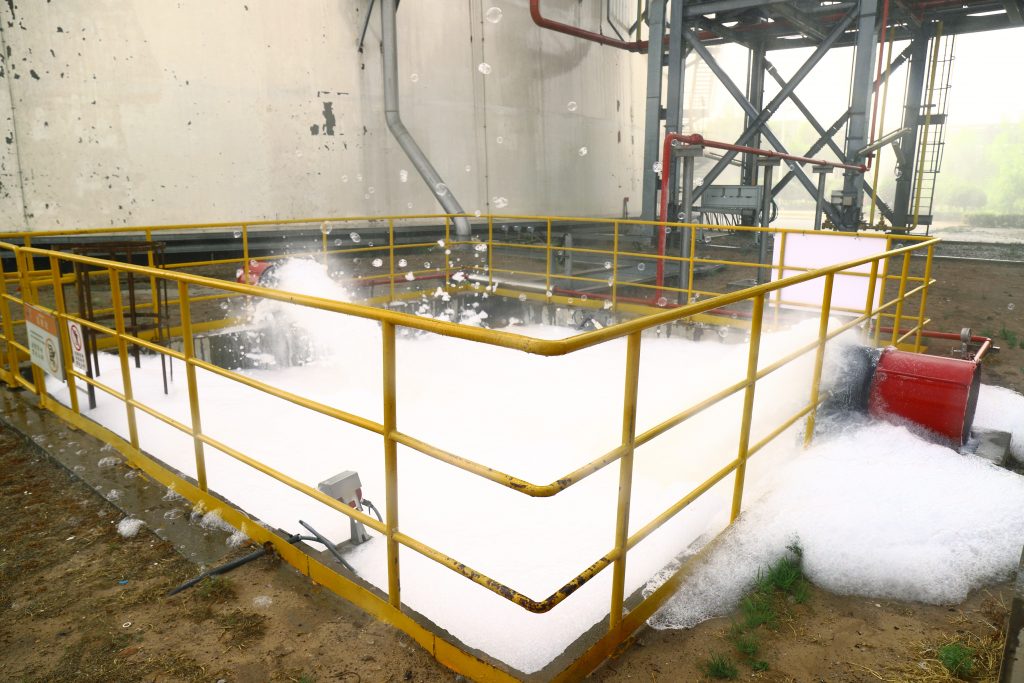

The drill officially began at 10 am. The combustible gas detector in the LNG storage tank pump area of the GDS system in the central control room alarms, the LNG loading pump automatically interlocks and stops, the inlet and outlet shut-off valves of the storage tank automatically interlock and close, and the deluge system in the 015 area of the fire control system automatically triggers. The DCS operator immediately retrieved video surveillance and arranged for the on-site operator to observe the situation in a safe area. It was confirmed that there was a LNG leak and fire in the LNG storage tank pump area, and one person was injured and fell to the ground. The DCS operator immediately reports the emergency situation to the commander in chief, who immediately orders the activation of the company level emergency plan. The DCS operator immediately dialed 119 to alarm and quickly pressed the emergency broadcast of the entire plant. With the sound of the evacuation alarm, all employees urgently and orderly evacuated to the emergency assembly point. The emergency teams of the company quickly gathered, and the rescue team immediately put on a complete set of emergency rescue equipment and rushed to the scene, performing their respective duties, pulling warning lines, rescuing the injured, activating fire monitors and hydrants to dilute and shield the leaking area, and suppressing the fire. LNG overflows to the liquid collecting pool at the bottom of the storage tank, automatically triggers the foam system to start, and sprays high expansion foam to cover LNG.

After receiving the alarm, the development zone fire rescue team immediately dispatched 4 fire trucks and 21 firefighters to the scene of the incident for disposal. After arriving at the scene, the fire brigade quickly mobilized the first rescue force, several all terrain fire fighting robots and fire trucks were quickly in place, pulling the hose, loading the gun head, holding the nozzle, aiming at the target, and opening the Fire hydrant, all of which were done in one go. The fire truck raised its telescopic arm high, aimed at the LNG storage tank pump area, and “water hoses” rose into the air, creating beautiful arcs to spray towards the burning area. After close cooperation and collaborative operations between the company’s emergency rescue force and the fire rescue team, the injured were sent to the nearest hospital for emergency treatment. The gas leakage was controlled and eliminated, and the fire was quickly extinguished. The drill was successfully concluded.

After the drill, all employees of the company gathered at the emergency assembly point. The emergency drill evaluation team commented on the disposal work of each emergency team, and the overall commander summarized the drill. The propaganda personnel and volunteers of the fire brigade distributed fire promotion materials such as “Fire Cases” and “Twenty Common Sense of Fire Safety” to all employees of the company. Based on the characteristics of summer fire accidents, they explained the fire safety common sense in summer, reminded employees to regularly investigate fire hazards, do a good job in safety prevention, and strictly prevent the occurrence of fire accidents.

Through this practical exercise, the fire safety awareness, emergency response ability, escape and self rescue ability, and emergency response ability of all employees of the company have been further improved. At the same time, the ability to use emergency equipment, cooperate with each emergency team, and cooperate with external rescue forces has been effectively tested. Through “practice” to promote prevention and “practice” to prepare for war, a safety production atmosphere of “everyone emphasizes safety and everyone knows emergency” has been formed, Continuously improving the four capabilities of fire safety, focusing on building a well-equipped, professional and capable hazardous chemical emergency rescue team that can “pull, charge, and win” at critical moments, effectively ensuring the safe, stable, and long-term operation of the equipment, and ensuring the stable safety production situation of the jurisdiction and the company.